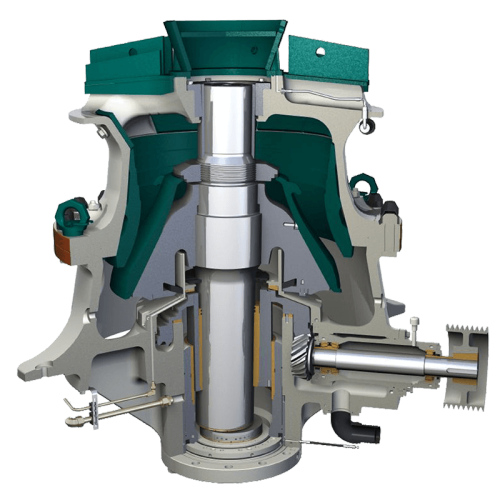

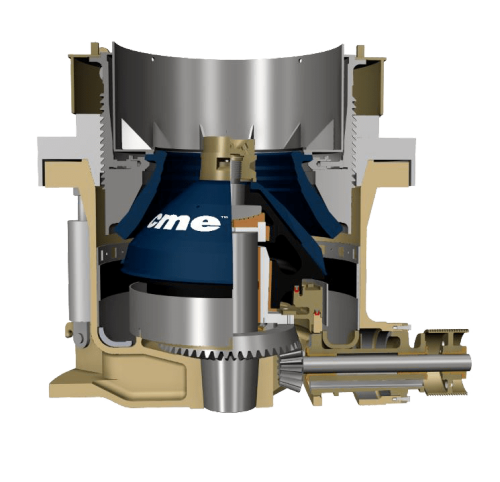

17/02/ · Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). A 60″~x~89″ crusher would have an opening dimension of 60 inches (152 cm) and a diameter across the base of the mantle of 89 inches (226 cm).

Learn More

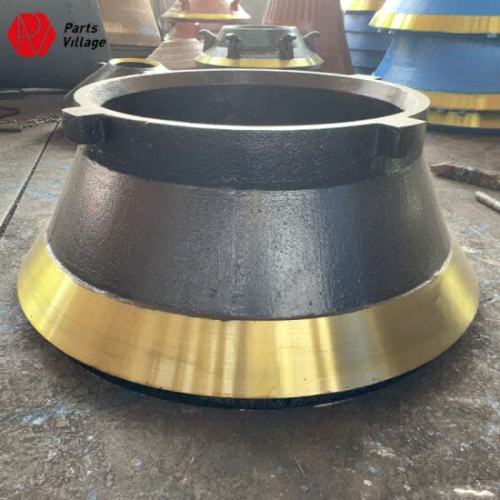

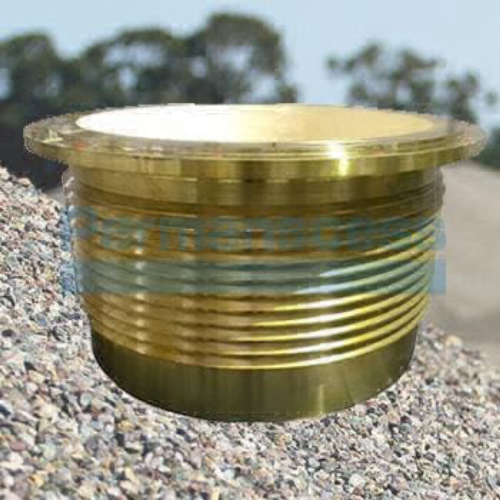

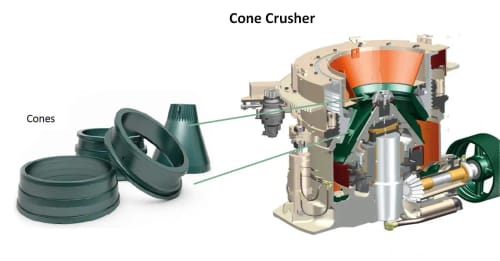

A cone crusher's linings should be replaced when they're at least one inch thick at the bottom and have begun to crack and disintegrate. When the liners are less than a half inch thick, a 10-percent decrease in production is an indication that it's time to change them.

Learn More

Technical specification ; Feed particle size, mm, 25, 25 ; Final particle size, mm, 2 - 10, 2 - 10.

Learn More

Jul 19, Cone Crusher Motor Sizing Hard limestone, having an impact strength of 15, is fed from a secondary crusher set at 3 -in. open side setting, producing stone having 80 : Cone Crusher cone crusher Cone crusher . The China cone crusher is a machine used for breaking big rocks into minor rocks, gravels or rock dusts.

Learn More

adjust a cone crusher windsunglas. May 16, · Jaw Crusher How To Adjust A Cone Crusher Crusher Mills how to adjust stone size rock crusher cone and maintenance Cone Crusher,

Learn More

Cone crushers are only altered in the space between the mantle and side. These settings are called the OSS (open side setting) and CSS (closed side setting.) The gap on the side that is open determines the size of the largest particle of the finished product.

Learn More

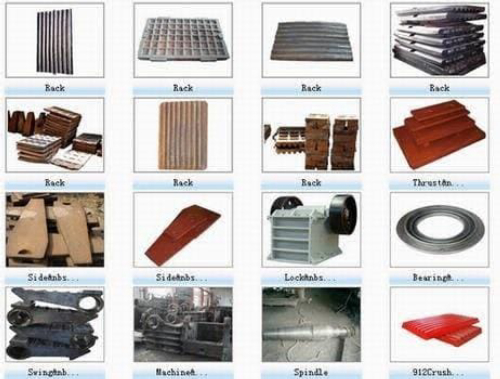

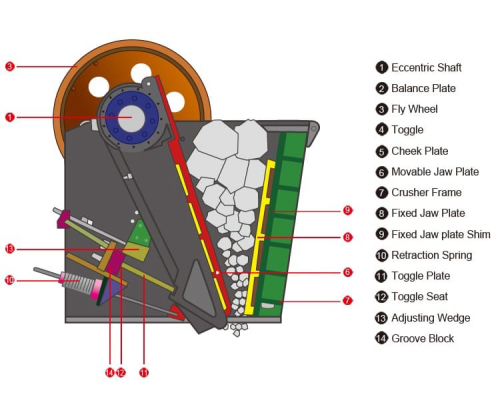

To complete jaw crusher liner replacement should to avoid damage in cutting cone plate process when the cone lining plate installed the adjustment ring cone at the lower part of the lower lining keep the gap between 1 2 mm between the plate and the cone lining the top installed should be first nut is installed and then cast zinc alloy.

Learn More

1a). The size reduction process in a cone crusher, on the other hand, evolves like a series of crushing events. It simply occurs by the rotation

Learn More

Multiply the product from step (9) by the tons per hour to obtain the gross hp required. Cone Crusher Motor Sizing Hard limestone, having an impact strength of 15, is fed from a secondary crusher set at 3¼-in. open side setting, producing stone having 80 percent minus 3¼-in. The product of the secondary crusher is screened at 5/8-in.

Learn More

2) CSS - as noted above, use a Ball or "Slug" made of tin foil to drop through the lowest nip point with the crusher running. by rope. similar to gaping a cone

Learn More

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market. Crushing Jaw Crushers

Learn More

For small and medium-sized cone crushers, the maximum distance from the feeding equipment to the top of the crusher is about 0.9 meters. If the feeding distance is too large, the stone will easily impact the crushing cavity at high speed, causing impact load on the equipment, resulting in additional maintenance costs and low output.

Learn More

29/05/2022 · Cone crushers can be altered in the space between the mantle and the side. These settings are known as the OSS (open side setting) and CSS (closed side setting.) The size of the largest particle in the finished product is determined by the opening on the side that is open.

Learn More

09/09/2022 · In order to obtain appropriate “load bearing positioning” and maximize productivity, the actual power of cone crusher should be maintained between 40% and 100% of the rated power, and 75% to 95% of the rated power is the best choice in operation. The feeding point needs to be aligned with the center point of cone crusher.

Learn More

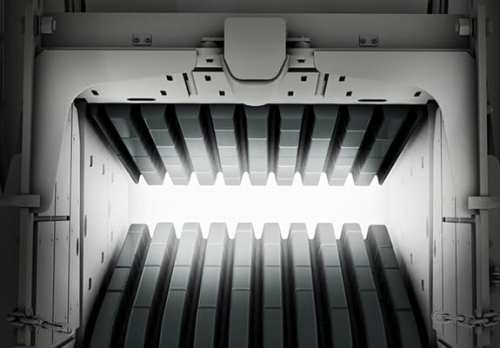

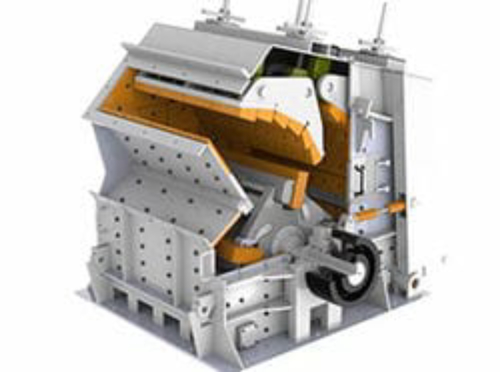

20/07/2022 · The following is a detailed description of the discharge control modes of jaw crusher, impact crusher, cone crusher, hammer crusher and roller crusher. Jaw crusher. It is a common coarse crusher. The size of the discharge port determines the size of the crushed stone and the production capacity of the equipment.

Learn More

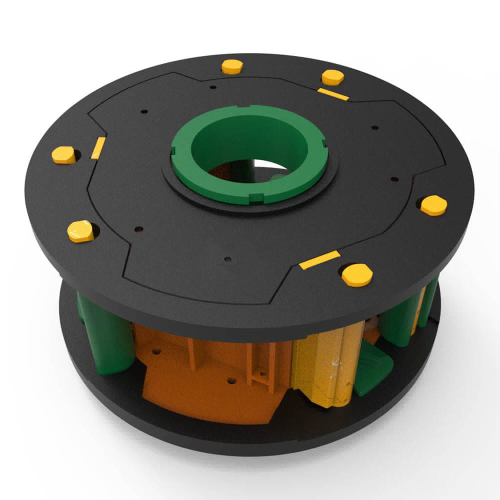

10/08/2022 · Single cylinder cone crusher Multi-cylinder cone crusher Cone crusher advantages: 1. Reduce downtime Due to the safety device, it greatly reduces the downtime. At the same time, the body is a cast steel structure, and reinforcement bars are arranged in the heavy load parts. 2. High production efficiency

Learn More

11 oz. Electric Dual Blades Silver Ice Crusher Snow Cone Machine Treat your guests to a wonderful snow cone Treat your guests to a wonderful snow cone or fancy cocktail with VIVOHOME automatic ice shaver. Simply plug in, add ice cubes, and press the handle for hassle-free shaved ice. Designed for countertop use, the sleek and classic ice shaver

Learn More

Stationary Cone Crushers Market Research Report is spread across 113 Pages and provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

Learn More

The liner as the easily damaged parts of the cone crusher, if it was evenly worn down to about 2.5cm, we should consider replacing it. Because the liner made of manganeses will crack when it about 1.6-1.9cm thick. Then causing the lining plate to

Learn More

Cone crusher size reduction control (Itävuo et al., , Itävuo et al., ) was realized using a discrete-time I controller 2 in velocity form (Åström and Hägglund, 2006) to avoid the undesirable process upsets in case of measurement errors and measurement noise.

Learn More

Depending on the specific cone crusher, the maximum feed size is up to 300 mm, resulting in a finished product with a grain size of between 3 mm and 60 mm

Learn More

The cone crusher’s optimised speed and improved crushing chamber design provides high productivity with less we parts, meaning a great savings in labour. The adjustable crushing chamber can provide the required size of material, and is able to meet a variety of customer needs. AUTOMATION SYSTEM

Learn More

DYNAMIC EQUIPMENT CONE CRUSHER RANGE ; DYNAMIC SPRING CONE CRUSHER · Sizes available: 2ft; 3ft; 4ft & 4 1/4ft; 5 1/2ft; 7ft ; DYNAMIC HIGH CAPACITY CONE CRUSHER.

Learn More

How to improve the output of cone crusher is very important. The crushing output of the cone crusher can be adjusted by adjusting the size of the closed side discharge opening. The smaller the size of the closed side discharge port, the smaller the output of the cone crusher, and the better the quality of the finished material discharged.

Learn More

To form the cone, a set of imaginary circles are placed along the forecast track at the 12, 24, 36, 48, 72, 96, and 120 h positions, where the size of each circle is set so that it encloses 67% of the previous five years official forecast errors. The cone is then formed by smoothly connecting the area swept out by the set of circles.

Learn More

If it is a large stone production line and the material is hard, it is better to choose a cone crusher. If the particle size requirements are very strict, you can add a Vertical shaft impact crusher. Written by Rayco. 20 years of experience in the mining and construction aggregate industry, to provide advice on your mining or quarry projects.

Learn More