Using crusher backing material to help change liners of 1000 maxtrac cone crusher.

Learn More

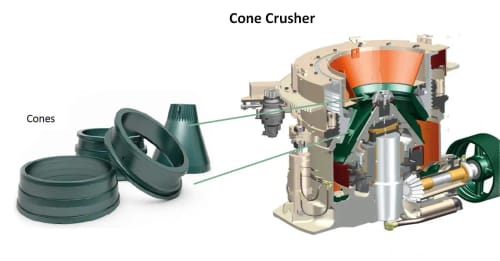

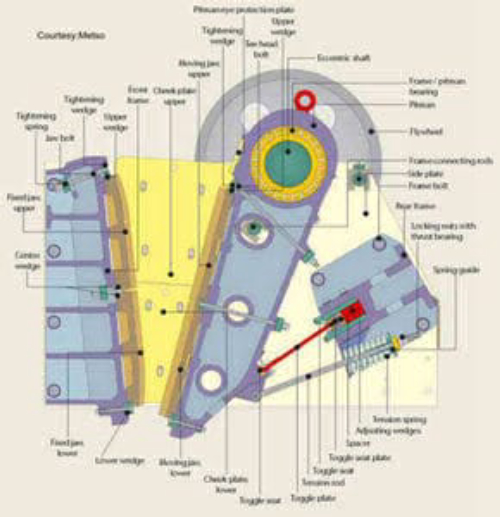

Replace the cone crusher concave Blow liner removal Remove the bowl liners as follows: Remove the adjustment cap and the bowl earlier. Thoroughly clean the threads on the adjustment ring, clamping ring, and bowl, removing all traces of dirt, rust, and old grease. Lift the feed hopper from within the bowl.

Learn More

This Pin was discovered by Nanjing Manganese Manufacturing Co.;Ltd. Discover (and save!) your own Pins on Pinterest.

Learn More

How to change cone crusher liners? Normally, there are 6 steps to change cone crusher liners: On the first collection of brand-new linings, position a mark on the modification cap chauffeur ring where the pinion tooth reaches a motorist ring tooth when the target crusher setting has actually been accomplished.

Learn More

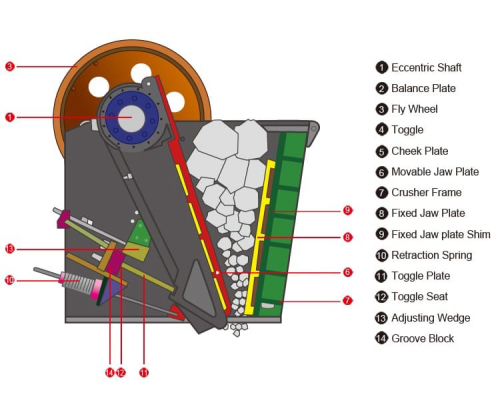

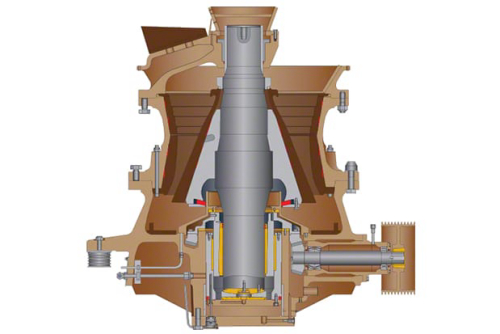

The geometry of crushing chamber is crucial for the performance. Due to wear, the geometry of the liner changes, which causes the close side setting (CSS) to

Learn More

Selecting a Cone Crusher liner There are numerous liners for both fine and coarse feeds. But which one you select will depend on a number of elements. The most crucial factor when it comes to Cone Shredder Parts selection is the feed. You must have a graded feed entering the crushing chamber. A well-graded feed is generally considered as:

Learn More

Cone Crusher Liners Makuri provides real solutions for cone crusher liners that go above and beyond the usual OEM standard profiles, leading to measurable improvements and lowest TCO every time. Unplanned shutdowns to change mainframe liners and arm guards —life doesn’t match main liners;

Learn More

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more

Learn More

May 05, · Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. but the change trend is different. The effect of the dynamic friction coefficient on the repose angle is obviously greater than that of the static

Learn More

Installation of new bowl liner • Make sure bowl liner is centered in bowl • Replace wedges (shim as needed) • Tighten in criss-cross pattern: check seat area with feeler gauge, pour backing if required and place insulation around wedges Mantle removal 1. Remove feed plate (feed cone) 2.

Learn More

When should I replace my Cone Crusher liner? If the liner is wearing evenly throughout the chamber, you should consider changing out the manganese when it has worn down to about 1" (2.5 cm) thick at the bottom. At about 3/4" to 5/8" (1.9 to 1.6 cm) thick, the manganese will crack, causing the backing material to begin to disintegrate.

Learn More

1.Cone Crusher Liners: How to Select and When to Change; 2.World-Leading Crusher Liners – CMS Cepcor; 3.Cone Crusher Liners | Crushing Wear Parts – Cast Steel Products; 4.Cone Crusher Wear Parts – Columbia Steel Casting Co., Inc. 5.Replacing the liner of a HP cone crusher – Outotec; 6.Yong Won SP300 Super Cone Crusher liner

Learn More

Our relationship with multiple foundries minimizes risk and ensures the best price with liners made to our quality requirements. Optimum Crush® liners have led to as much as 50% increased life and/or 10% increased production. In nearly 100% of the tests conducted with Cone Crusher bowl liner, they have met or exceeded the current product.

Learn More

Dec 27, · How To Choose. 90 to 100 percent passing the closed-side feed opening. 40 to 60 percent going through the midpoint. 0 to 10 percent leaving the closed-side setting.

Learn More

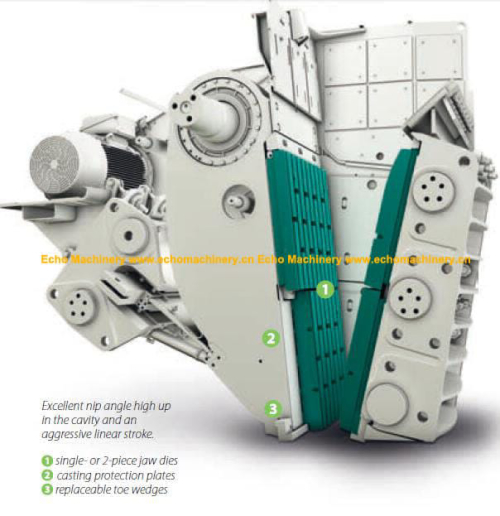

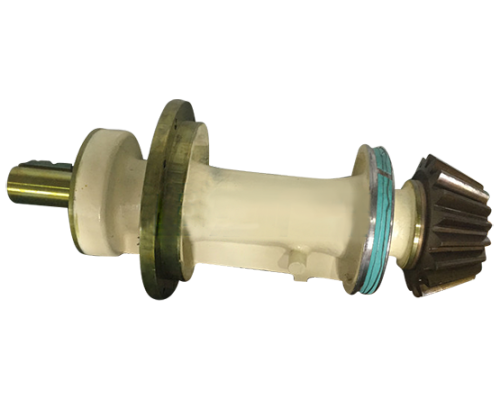

Liner change Dismantling of crusher Technologically unique, the new generation cone crushers offer unprecedented performance. Their safe and easy maintenance ensure maximum reliability. 5 19 - Antispin device 20 - Head 21 - Upper head bushing 22 - Mantle 23 - Hydraulic adjustment motor 24 - Bowl liner 25 - Bowl liner fixation

Learn More

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn More

Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these

Learn More

competitor supplied crusher liners, across all three cone crushers. ™ lifting device when liner change-outs are required.

Learn More

As cone crusher liners wear, the operator threads the bowl inwards, price of the liner change you should consider changing the liners. Wholesale Price Cone Crusher Liners. 3. When changing the lower copper sleeve of the movable cone and the eccentric sleeve bushing, you must first check whether the inner diameter of the movable

Learn More

A good indication the Cone Crusher liners need to be changed is when there is a 10% or more drop in production level or throughput. Liner thickness Depending on the application, If the

Learn More

Made to fit, reduced downtime and ease of replacement - Precise fitting for less wear and te equipment and for quick and easy replacement. Increased crusher uptime - Replacement and Custom Design and Proprietary alloys offer proven increased crusher efficiency, prevent premature erosion, and extend usable wear life.

Learn More

As cone crusher liners wear, the operator threads the bowl inwards, price of the liner change you should consider changing the liners.

Learn More

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, We offer high quality replacement wear parts for cone crushers,

Learn More

10 Steps To Install Cone Crusher. During installation, place the cone-shaped liner plate, place the thread ring on it, place the flange on the thread ring, clamp the snap ring on the outer neck ESCO CRUSHING - L.S.W. Wear Parts Ltd. Contact L.S.W. Wear Parts Ltd. for pricing and information.. Cone Crusher Wear Parts Cone Crusher Accessories.

Learn More

Click the image below to earn more. ELRUS Manganese Cone Liners. Topics: Downtime, crusher spare parts, gravel crushing and screening costs,

Learn More

If you're like most sites, your maintenance team removes the crusher mainshaft to replace the liners away from the crusher. Our mantle lifting tool makes it

Learn More