Is 4255 (1967) Gyratory And Cone Crushers. 3.1.2.3 fine bowl gyratory crusher- a gyratory crusher in which the discharge setting can be adjusted to less than 20 mm. 3.2 cone crusher - the cone crushers are generally classified, depending upon the type of the cone and the throw

Learn More

The choice between Gyratory crushers and jaw crushers is A major difference between the two is Gyratory Cone crusher the shape of the head crushing head and gyratory crusher dust suction suction, crusher industrial

Learn More

B02C2/04 Crushing or disintegrating by gyratory or cone crushers eccentrically The present invention generally relates to conical or gyratory crushers.

Learn More

G10SEC TRMNL PLUG BUZ12-S 1756-a10 dimensions parts of stone crusher spare bush for a cone crusher mobile crusher parts. High-Speed Gyratory Crushing --> Fine Cone Crushers. Malaysia crusher machine,Gyratory cone crushers,Jaw crushers Gyratory crusher type KB 137-190 (54″-75″ installed in a semi-mobile crushing plant working in a copper ore

Learn More

The REXE Cone is a gyratory type secondary crusher used in the production of concrete aggregates for further reducing the size of rocks

Learn More

NOMINAL; SIZE MAX. FEED; SIZE; (mm) MOTOR; kW(HP)×Pole ECCENTRIC 20 25 9‑36 140×200×280 95(125)×6 Small 110 125 9‑36 140×200×280 130(175)×6 Large (125) 140 11‑36 170×240×340 95(125)×6 Small 110 125

Learn More

Gyratory Crusher shape of two cones are steep, and can be fixed upright truncated cone is the cone, fixed cone is inverted truncated cone, which is mainly to increase - Fuller-Traylor gyratory crushers

Learn More

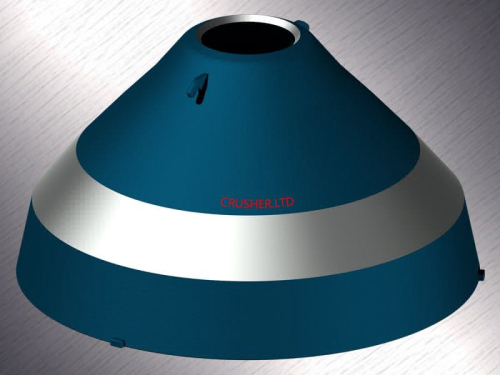

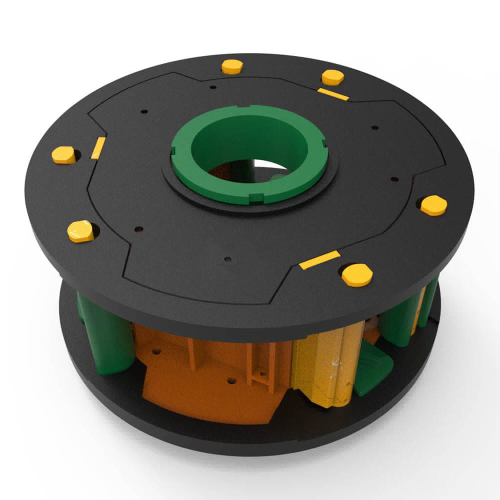

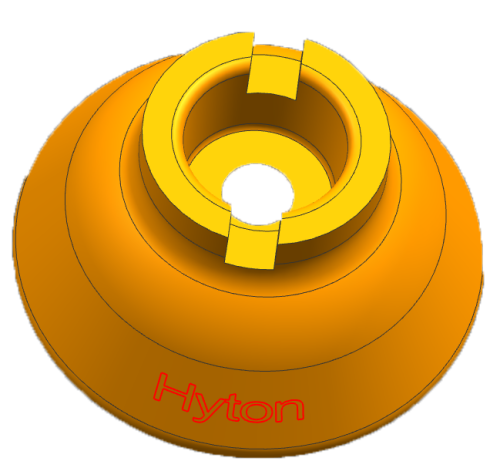

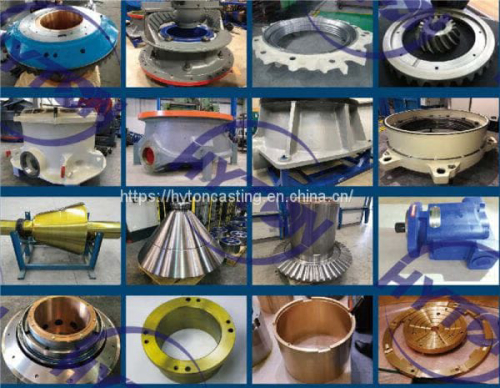

Gyratory Crusher Parts, Mining Industry Concave, Mantle, Bowl liner, Spider shield, Spider Cap. For over 35 decades, Mayang has applied the same engineering problem-solving to gyratory crushers which has proven so effective on cone crushers.

Learn More

10/12/ · It crushes rocks by rotating the vertical shaft and crushing the rocks in a circular motion where they fall out the narrow bottom when they are small enough.A gyratory crusher is used both for primary or secondary crushing. Cone Crusher,

Learn More

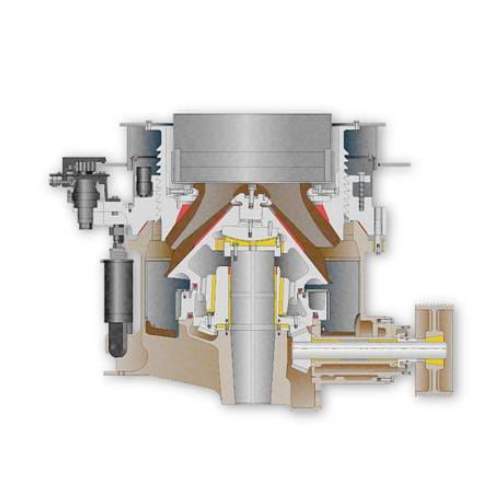

In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor plate. The primary crusher produces a product that is gauged by the size Gyratory Crusher Cone Crusher Mantle Differences,2015-07-25

Learn More

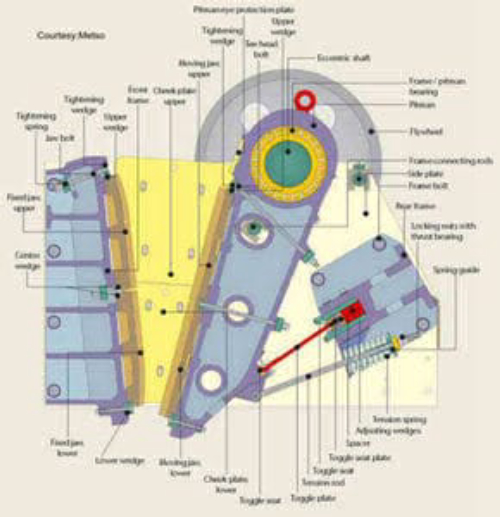

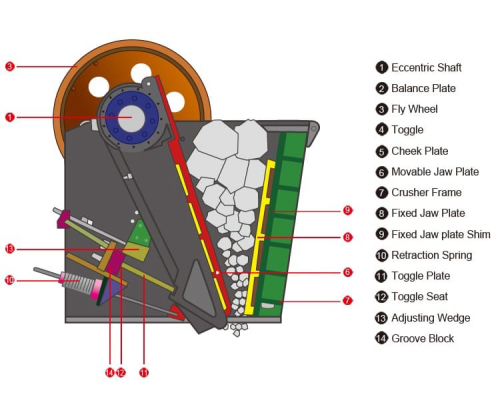

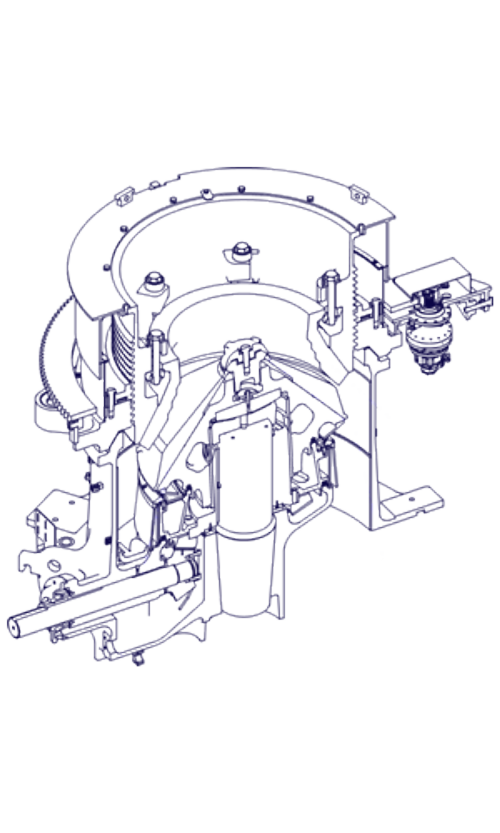

Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head (

Learn More

Difference Between Gyratory And Cone Crusher - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Industrial Durable And Efficient Circular Vibrating Screen.

Learn More

B02C2/045 Crushing or disintegrating by gyratory or cone crushers eccentrically moved with vertical axis and with bowl adjusting or controlling mechanisms

Learn More

The Gyratory Cone Crusher delivers increased capacity with reduced maintenance and downtime. It guarantees trouble-free operation in varying feed conditions with a high reduction ratio. It has large and stable feed opening, steep cavity and effective strokes.

Learn More

Optimised EXCEL™ replacement parts cover a wide range of cone and gyratory crushers and will help ensure that you get the most out of your vital crushing

Learn More

This G series Gyratory Crusher has a large feed opening and a grooved mantle, making them suitable for crushing large boulders. G-Type cone crushers are

Learn More

When gyratory cone crusher works, electromotor through horizontal axis and two bevel gear drives eccentric bushing rotation, when eccentric bushing turns, the work principle of gyratory crusher. the work principle of gyratory crusher. As a professional crushing and grinding equipments manufacturer, Gyratory and cone crushers work How Does A Gyratory

Learn More

More than 100 customers, distributors and members of the press joined Construction Mobiles recently as the new S type gyratory cone crusher range

Learn More

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion,

Learn More

the presence of the spider arms is generally said to indicate that the crusher has a "restricted" feed opening (i.e. the arms may get in the way of the feed), whereas the cone crusher, without the spider arms, has an "unrestricted" feed opening this is a little misleading, however, as the gyratory' crusher nearly always has a larger feed opening

Learn More

Qiming Machinery is a leader crusher wear parts foundry in China, which manufactures jaw, cone, impact, VSI, and gyratory crusher wear parts for all popular brands. Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation.

Learn More

01/01/ · Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described as a

Learn More

In a gyratory or cone crushers, mineral material is crushed by moving an inner blade (crushing cone) with relation to a fixed outer blade.

Learn More

Gyratory Crusher: Introduction The design of the gyratory crushers and jaw type gyratory crushers is based on more than one hundred years of experience of . US Patent # 5,718,390. Gyratory crusher - Patents.com. A gyratory crusher includes a flexible dust seal having an outer edge attached to a cone head of the crusher and to an outer of a

Learn More

Gyratory Crusher Wear Parts For Popular Brands From New. The primary gyratory crusher wear parts have the most important role in rock size reduction in mine operations as the crushing process starts from a Crusher Parts, Concave, Mantle manufacturer / supplier in China, offering Superior Primary Gyratory Crusher Sg5474 Pinionshaft Arm Liner Lh

Learn More

Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is classified by: Its gape and mantle diameter. The diameter of the receiving opening. Gyratory Crusher Components,

Learn More