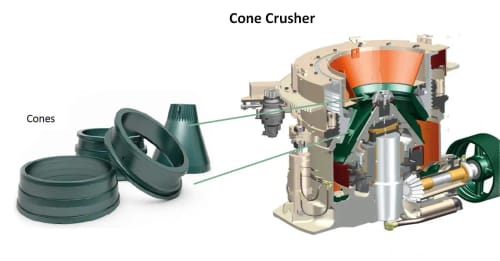

1. An improved mating mantle-bowl structure for a crusher wherein a drive unit provides a gyratory movement between said mantle-bowl structure to afford a crushing action, comprising: a mantle defined as a figure of revolution and including an externally defined conical section of substantially linear external taper and an external throat portion thereabove, said mantle

Learn More

Mantle - Mayang Crusher Parts. High quality and low price Mantle-Cone crusher wear parts

Learn More

MANTLE, 07-344-404-001, 610401. 14999-D, 610403. CONE AC 1384, MANTLE, 07-349-708-001, 610601. CONE AC 3-1/2 51, MANTLE, 11122-H, 610301.

Learn More

Mining Industry Concave, Mantle, Bowl liner, Spider shield, Spider Cap. For over 35 decades, Mayang has applied the same engineering problem-solving to

Learn More

than conventional Gyratory Crusher. Direct metal touch structure without backing material permits quick,easy changing of mantle and concave ring.

Learn More

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Higher throughput Increased speed, installed power and mechanical improvements. Reduced downtime

Learn More

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Particularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing

Learn More

17/02/ · Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). A 60″~x~89″

Learn More

1. An improved mating mantle-bowl structure for a crusher wherein a drive unit provides a gyratory movement between said mantle-bowl structure to afford a crushing action, comprising: a mantle defined as a figure of revolution and including an externally defined conical section of substantially linear external taper and an external throat portion thereabove, said mantle comprising a base metal

Learn More

26/04/ · Cone Crusher Mantle 183 open Crusher Jobs available on Indeed.com, the world’s #1 Job site. Crusher Wikipedia. A cone crusher is similar in operation to a gyratory crusher, Mantle is installed in the lower position and concave in

Learn More

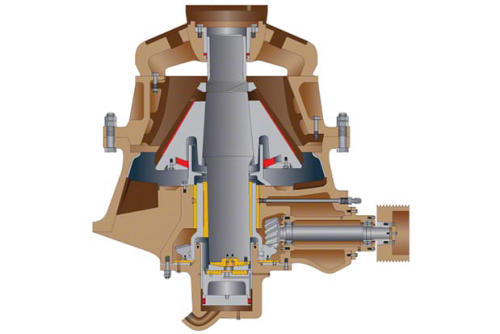

As exemplified by U.S. Pat. Nos. 2,883,218 and 4,034,922, a gyratory crusher typically includes a main shaft provided with a tapered portion which supports the crusher head or mantle through a correspondingly tapered internal bore extending through the mantle.

Learn More

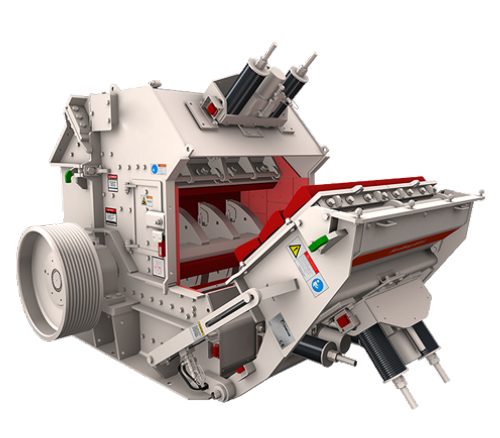

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crushing chamber below.

Learn More

Typically, a gyratory crusher comprises a stationary conical bowl (or mortar) which opens upwardly and has an annular opening in its top to receive feed material. A conical pestle, opening

Learn More

gyratory crusher liner mantle manufacturer/supplier, China gyratory crusher liner mantle manufacturer & factory list, find qualified Chinese gyratory crusher liner mantle manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com.

Learn More

Jaw gyratory crushers - design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

Learn More

each mantle. Since H-E Parts improved the material selection and implemented a mantle and concave redesign, the following has been achieved:.

Learn More

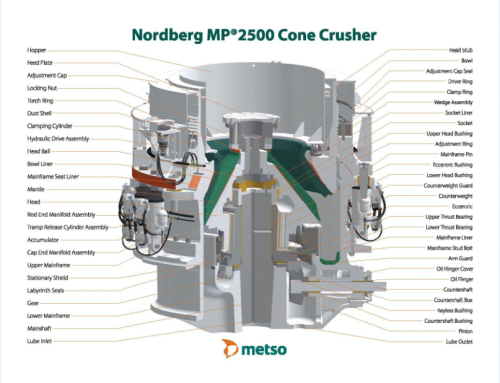

The design of our gyratory crushers and jaw gyratory crushers is based on over Gyratory crusher. Weights 1). Type. Feed opening. Mantle diameter.

Learn More

superior gyratory crusher features 1 crushing chambers are matched to each individual application, optimizing crushing performance 7 patented headnut with burning ring allows for simple removal of the mantle 2 manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 high-strength shell design,

Learn More

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Top models for sale in HILLSBORO, OREGON include C3R and C4

Learn More

25/07/ · While the Secondary and the Tertiary crusher’s travels between 500-600 R.P.M. This difference in the speed results in a HAMMERING type crushing action over the SQUEEZING

Learn More

Gyratory Crushers. Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an

Learn More

Based on this design, our TIC insert mantle span life can be 2-3 times than normal manganese gyratory mantle. Gyratory Concave Designs We use the hardest alloy that will withstand the impacts of a specific gyratory application. This depends on the compressive strength, toughness, and friability of the material being crushed.

Learn More

Superior™ MKIII 60-89 primary gyratory crusher provides increased throughput coming from increased speed and installed power that brings overall benefits to your primary crushing circuit. High throughput Reduced downtime Fast wear parts exchange Increased safety

Learn More

gyratory crusher line Mar 01 · The gyratory crusher is designed to operate at the same discharge setting throughout the life of the mantle and concaves it is NOT designed to operate at a Gyratory Crusher Mantle - Crusher. A&S Wear Parts Australia Pty Ltd is a global supplier of Gyratory Crusher Mantle, Focusing

Learn More

Proper design of both gyratory crusher mantle and concave liners leads to lower and more consistent crushed product size, better throughput, highly predictable liner changeout intervals and overall better asset utilisation. Previous Next Concaves Previous Next Mantles Previous Next Mainframe liners

Learn More