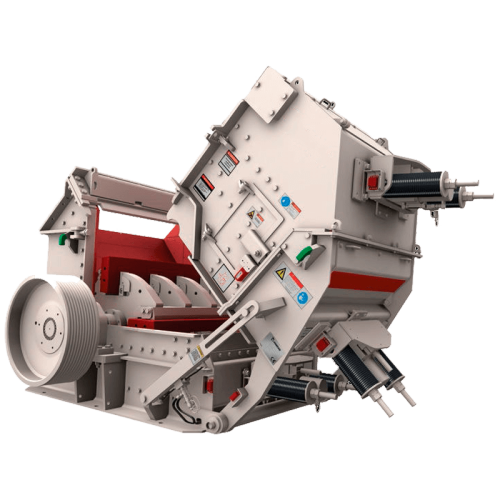

jaw crusher machine is made of hardened steel (high carbon steel). It puts the moveable jaw stock in motion (through the motor, pulley. and belt

Learn More

08/07/2022 · aj series jaw crushers CITICHeavy Industries Co. Ltd. Dec 8, The design of the AJ series uses a bolted and pinned frame assembly, with The AJ series Single toggle jaw crusher incorporates the use of the hybrid however please consult CITICHIC for your specific requirements. jaw crushin machine – tisl.

Learn More

The DT (Double Toggle) Model Jaw Crusher is unique in that it has its hinge The advantage of this design is that when the movable jaw Jaw crushers,Jaw breaker, Primary,Mobile,Stone jaw crusher Double Toggle jaw crushers may feature hydraulic toggle adjusting mechanisms. Our design and production are of high position both at home and abroad.

Learn More

The shaft of a typical jaw crusher machine is made of hardened steel (high carbon steel). It puts the moveable jaw stock in motion (through the motor, pulley and belt arrangement) that produces the needed force to crush materials. Components of jaw crusher

Learn More

07/01/ · Would love to be able to make my own crushed stone and gravel. I have screened piles of rock while excavating my house site. I am trying to build a jaw cru

Learn More

Rock Crusher New Design Mining Machine Jaw Crusher Stone Crushing Line Factory, Find Details about Crusher, Pev Jaw Type Crusher from Rock Crusher New

Learn More

On Earth, scaled-up rollerjaw rock crushers could be used in mining and rock-crushing operations in which jaw crushers followed by roll crushers

Learn More

It's a long one! I had previously gone over the function and basic assembly of the rock crusher, however in this video I go into a lot more detail and show

Learn More

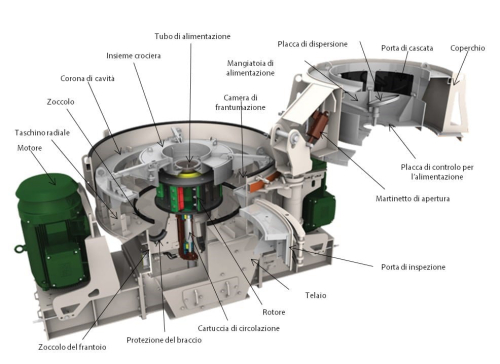

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws.

Learn More

Jaw crushers are designed to process abrasive hard rock, with aggressively-shaped nip angle, it featurs the crushing ability that can consistently reduce high hardness materials the in the quarrying, mining, recycling, and building materials industries, increases uptime. Hydraulic protection system

Learn More

Eagle Jaw Crushers eliminate premature failures to provide years of component life, durability, and reliability for your crushing applications. Processes abrasive hard rock, using the time tested overhead eccentric design. The short bearing span between the side frames reduces stress and shaft deflection.

Learn More

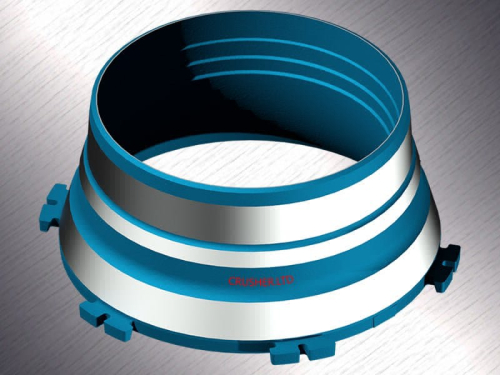

Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between 50 and 80 mm. Tertiary Crushing. This is the third stage of crushing. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself

Learn More

opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design. Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock.

Learn More

01/01/ · The jaw crusher is primarily a compression crusher, while the others operate primarily by the application of impact. 4.2. Design of Jaw Crushers. Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened steel.

Learn More

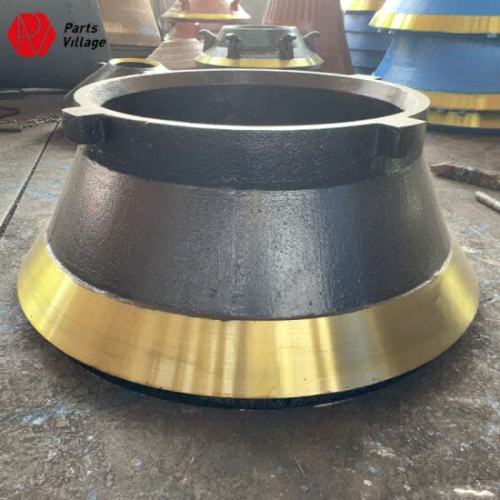

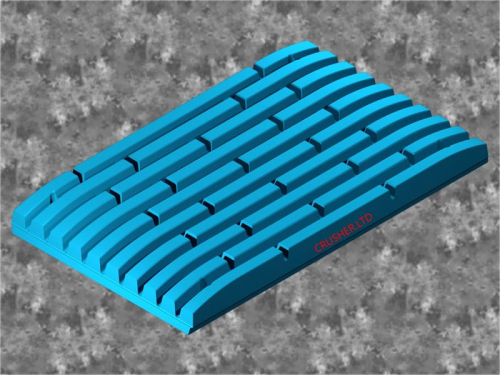

The entire design facilitates lubrication and replacement of shaft bearings. Jaw plates are constructed of manganese steel and have corrugated crushing surfaces which reduce the power required for fracturing material. The jaw plates are built into two pieces to jaw. Those on the swing jaw are interchangeable.

Learn More

21/07/ · 6. Quickly insert the 3-foot iron rod into the cement. Move it until it stands at the center of the pipe. You may have to prop it in place by fixing a C-clamp to it and laying the clamp on the top

Learn More

jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates. This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanism.

Learn More

The jaw crusher is a rocks or lumps reduction machine The design and construction of a prototype rock crushing machine was performed

Learn More

08/11/ · We have this rock crusher for sale in our store. DIY Rock Crusher. Every part of this small homemade rock crusher. All components of the rock crusher are ready to assemble

Learn More

Simplicity of design and rugged construction has made jaw crushers ideal This 1″ x 2″ homemade rock crusher is mini in size but large in crushing

Learn More

Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the application. We have many case histories in which wear life increases of 50% are common, and some in which wear life increased up to 300%. Columbia Steel offers more jaw crusher plate styles than any manufacturer in the industry.

Learn More

The 911MPETMBT75 is our largest Laboratory Jaw Rock Crusher and is based on our world-renowned High Reduction Ratio Jaw Crusher, the 911MPETMBT75 has been engineered to

Learn More

The jaw crusher design includes a set of two vertical jaws—a fixed (stationary) jaw and a swing (reciprocating) jaw. The swing jaw moves back

Learn More

20121126Primary jaw crushers are typically of the square opening design and secondary jaw crushers are of the rectangular opening design. However there are many exceptions to this general rule. A Jaw Crusher reduces large sie rocks or ore by placing the rock into compression. A fixed jaw mounted in a V alignment is the stationary breaking surface

Learn More

jaw crusher animation jaw crusher animation This post is called jaw crusher animation . You can download all the image about home and design Visit.

Learn More

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary

Learn More