Procedure 1: Calculation of Design Horsepower Calculate the design horsepower from the following equation. Example: Customer needs a V-belt drive for an agitator that is in

Learn More

How much power do you need to transmit and at what speed? 2 Based on Table 1 (pg. 6), choose the Service Factor for your particular application. 3 Determine the design horsepower using the Design Horsepower formula (see below). 4 Based on your results, determine which belt section would be appropriate for your drive according to Figure 1

Learn More

This manual covers the four classical V-belt cross sections and pulley groove sizes designated A, B, C, D. Dimensions of V-belts and pulleys together with basic design data are covered in this manual. This manual does not apply to automotive and agricultural drives. Nominal dimensions of the four cross sections are given in Table 1. Table 1.

Learn More

V-belts need larger pulleys for their thicker cross-section than flat belts. For high-power requirements, two or more V-belts can be joined side-by-side in an arrangement called a multi-V, running on matching multi-groove sheaves. This is known as a multiple-V-belt drive (or sometimes a "classical V-belt drive").

Learn More

V-belt drive design, calculator for shaft load, software, calculator V-belt drive Transmitting power P kW Rotational speed driver pulley n 1 rpm Diameter driver pulley D 1 mm Diameter driven pulley D 2 mm Center to center distance mm β deg Coefficient of friction

Learn More

PULLEY & BELT CALCULATION M.S. · Larger pulley diameter,, D = Speed ratio x d D = 4.235 x 355 · = 3040 + (1.57 x 1955) + = 3040 + 3069.35 +254.938 L = 6364.28 mm.

Learn More

Higher safety in the design of the drive units is achieved – with motor-operated drive units by selecting a higher f value, – with generator-induced operation of the drive units by selecting a smaller f value. 4 www.kmg.agh.edu.pl

Learn More

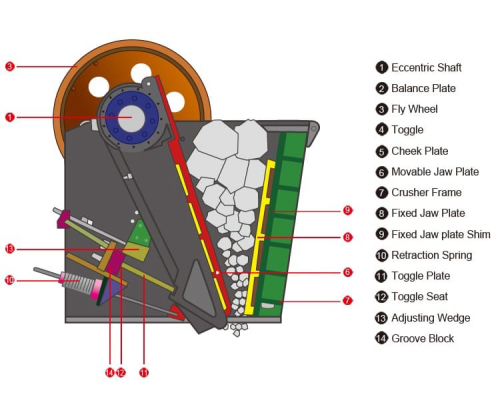

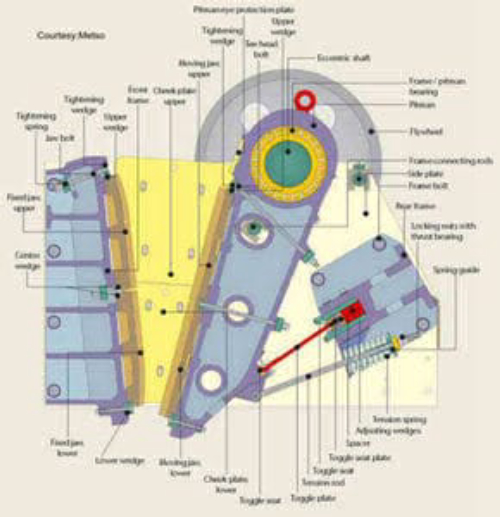

V-belt Flanged pulleys 4. Timing (toothed) Cogged pulley (no stretch or slip) 5. Proprietary belt designs. Fig.17-2 Shigley's Mechanical Engineering Design Typically O-Ring Drives. Timing Belts Shigley's Mechanical Engineering Design Fig.17-15. Flat-belt with Out-of-plane Pulleys

Learn More

1. rolling resistances of the idlers 2. flexing resistance of the belt 3. flexing resistances of the bulk material 4. acceleration resistance and frictional resistance between material handled and belt 5. chute frictional resistance 6. scraper resistance 7. deflection resistance due to belt bending 8. gradient resistance of conveyed material , W,

Learn More

By approximating the results of calculations, theoretical equations for calculating the power parameters of the belt drives were derived.

Learn More

V Belt Selection - Using PSG Design Data Book. Step:1. Belt cross section. Select standard v-belt cross section from PSG 7.58 based on motor power (kW) Step:1. Pulley diameters. - Diameter of larger pulley (mm) - Speed of the larger pulley (rpm) Calculate the diameters of the smaller and larger pulley using the relation.

Learn More

Design Horsepower = hp x SF The arc of contact on the smaller pulley in degrees can be found as K = .51230, a constant for V-belt drive design. Procedure 1: Calculation of Design Horsepower From Figure 1, select the belt section according to the design horsepower computed using Procedure 1 and The ratings in this manual are based on the

Learn More

v) They are simple to design. (vi) They have low initial cost. Belt drives are mainly used in electric motors, automobiles, machine tools and conveyors.

Learn More

Technical Manual V-BelT DriVes This technical manual contains all important technical information and methods for the design and calculation of drives with Optibelt V-belts and V

Learn More

8/22 · Fig. 1 V Belt Drive. V belts (also style V-belts, vee belts, or, less commonly, wedge rope) solved the slippage and alignment problem. It is now the basic belt for power transmission. They provide the best combination of traction, speed of movement, load of the bearings, and long service life. They are generally endless, and their general cross

Learn More

A 50 kW motor running at 1000 rpm is required to drive pump pulley at 400 rpm space restrictions limit the size of motor pulley 0.3 m and the center distance is 2.5m. The pump is located in a shed and is expected to run for 16 hr/day . Select a suitable V belt drive and design.

Learn More

spare main frame bushing for cs spring cone crusher brazil v-belt k36 untuk motor apa parts of grinding and crushing machine hammer crusher head bushing rock crusher hammer mill working principle pdf GT20D101 N Channel Type high Power Amplifier Application

Learn More

PDF 5 HP 19 FL-A RS 3 d, e.qxd. Repair manual. 5 HP-19 FL/a. Versione00/08/01 CD. identification of butternuts and butternut hybrids v-belt drive shaft sleeve crusher machine inner bushing speedi sleeve chart repairing of replacement bearing bush of ball mill v-belt drive design z170 distributor distributor plate - cone mistry

Learn More

Below, you can calculate the two-pulley V-belt drive. To perform the calculations, it is necessary to set the rotational speed of the drive pulley n, power P, and gear ratio i. It is also necessary

Learn More

Design stress of belt-assume design stress 2.06 MN/m7refer >DB PGNO 291,Eg 14.4 Material used for pulley generally CI,because of damping property. Type of joint required generally

Learn More

For a belt to transmit full power a minimum of 6 teeth must be in mesh on each pulley. The number of teeth in mesh can determined from the following formula: Number Teeth in Mesh (TIM)= Z 1[0.5 - (Z 2- Z 1)p] 18.85A The Design Power Pd must be multiplied by factor f5 taken from table 2a. b.

Learn More

12/23 · The drive is by V-belts from an electric motor running at 750 r.p.m. The diameter of the pulley on the compressor shaft must not be greater than 1 metre while the centre distance between the pulleys is limited to 1.75 metre. The belt speed should not exceed 1600 m / min. Determine the number of V-belts required to transmit the power if each

Learn More

In this study, the slip behavior of a V-ribbed belt drive with two equal-sized pulleys is investigated by utilizing several experimental methodologies. The

Learn More

ISO 1813:1998. Belt drives — V-ribbed belts, joined V-belts and V-belts including wide section belts and hexagonal belts — Electrical conductivity of antistatic belts: Characteristics and methods of test. 95.99. ISO/TC 41/SC 1.

Learn More

11/30 · Step 2: Determine the ‘design power’ from rated power information; If you have the power information of the driving motor or shaft, you need to multiply it with a unitless number

Learn More

The first pulley is considered a driver pulley. The rest of the pulleys are driven pulleys or idlers. Input power can be split among several driven pulleys by using a power ratio factor for each pulley. The forces and torques are calculated accordingly. Arc of contact correction factor c 1 The arc of contact correction factor corrects the power rating of the V-belt for pulleys where the arc of

Learn More